Case study central compensation (chemical industry)

In the current case study, the LBANK product is presented. A compact and cost-effective solution for reactive power compensation in industrial medium-voltage networks. This plant is suitable for outdoor installation and transportable.

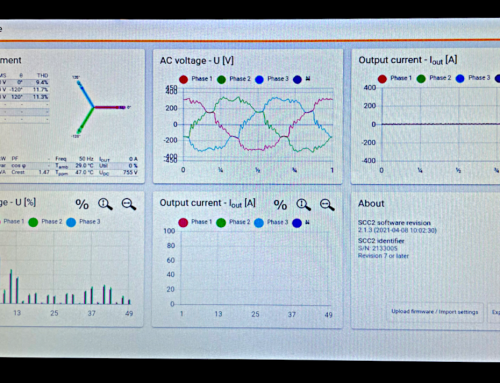

Energy quality with MIKA – LBANK

Three-phase choked compensation system for use in modern industrial networks with harmonic loads

the outdoor solution

Local conditions

The chemical and pharmaceutical industries are among the largest energy consumers in the manufacturing sector. In order to survive in international competition, this industry is also forced to rethink its ecological and business management considerations.

In all studies, an absolute MUST factor is energy-efficient production and the best possible use of existing electrical network infrastructures. Complication: The waste heat cannot be sufficiently dissipated from the plant and switchgear rooms on site, and the space required to install compensation equipment is limited. Thus, an indoor facility cannot be considered. A robust and easy-to-handle solution is needed that can withstand both ambient atmospheric conditions and maritime weather. A change of deployment location should also be possible with minimal effort.

Customer problem

Customer request

To be able to ensure trouble-free operation and more efficient use of the existing network infrastructure,

product requirements for the solution concept were defined, such as:

Our solution

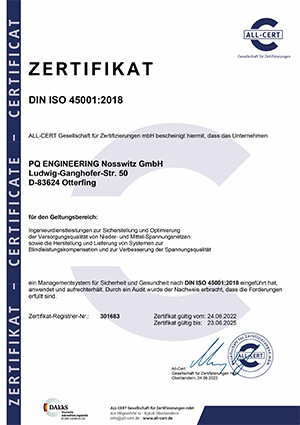

Simply clever! A simple, robust and well thought-out solution concept was exactly what was needed here. The wishes expressed by the customer were fully implemented in the layout and design of our plant. The result is a solution concept ideally tailored to the chemical industry and its needs. Choked capacitor unit: 5300 kvar at 6.0 kV / 50 Hz / 1-transport unit / Plug & Play

The solution concept can be quickly and easily moved from one production site to another, taking into account the climatic and chemical air compositions. The climate concept of this plant is based on convection cooling and does not require any additional heating in winter or forced cooling in the summer months.

In the sense of the 4A concept of PQ ENGINEERING the problem was analyzed, the solution was designed and delivered and supported in the after sales service – everything from one source!